Fls Raw Mill Roller Mill أستراليا

-

لاتترددفيتقديماستفساركفيالنموذجالتالي. وسوفنقومبالردعليكفيغضون 24 ساعة.

Vertical roller mills FLSmidth Cement

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the

[خذ المزيد]

Detailed Review of FLS OK™ Raw and Cement Mill

The FLS OK™ Raw and Cement Mill is a renowned equipment in the cement industry, known for its reliability, efficiency, and versatility. This detailed review aims to provide

[خذ المزيد]

GEARS AND DRIVES Driving simplicity - FLSmidth

2018年12月6日 Vertical roller mills (VRMs) are established worldwide in cement plants for the production of raw meal and in the cement grinding process. Contrary to other

[خذ المزيد]

Flexible milling and grinding solutions that last FLSmidth

The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality, simplifying spare parts inventory and facilitating easy switching of parts between vertical

[خذ المزيد]

Premium solutions for the cement industry - FLSmidth

FLSmidth is your premium provider of complete plants, upgrades, market-leading products and customised service offerings for efficient, sustainable cement production.

[خذ المزيد]

Vertical Roller Mills - FLSmidth

What is new regarding Vertical Roller Mills? Join us to learn about the latest developments in operating and maintenance practices as well as new innovations. Topics include recent

[خذ المزيد]

FLSmidth Touts Competitive VRM Market – Cement Products

2024年5月29日 Following the launch of this flagship VRM, three new OK Raw Mills were sold in 2018 – a strong indication that cement producers are favoring FLSmidth’s

[خذ المزيد]

FLSmidth well positioned in competitive VRM market

In 2018, FLSmidth sold 31 new vertical roller mills for all grinding applications. The combined cement grinding capacity of OK Mills from FLSmidth, grew by over 38 % from 2270 t/h in

[خذ المزيد]

PROCESS OPTIMISATION FOR LOESCHE GRINDING

2017年8月12日 Loesche – Innovative Engineering. For over 100 years the company Loesche has been building vertical roller grinding mills for grinding: Coal. Cement raw

[خذ المزيد]

Ball mills FLSmidth Cement

Ball mill for cement grinding. An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just that.

[خذ المزيد]

Vertical roller mill - ATOX® - FLSmidth MAAG

The rollers work harmoniously with a highly-efficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture level. A compact coal mill solution for grinding

[خذ المزيد]

Fls Ok Raw Mill Web 100817 [d47758w18742] - Documents

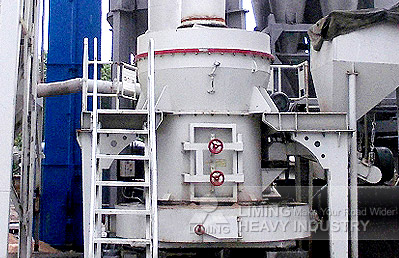

The OK™ mill has been FLSmidth’s standard cement VRM since 1993. Since its introduction the OK mill has proven to be the most efficient cement VRM available with the highest reliability and ease of operation. In 2017, FLSmidth introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement mill.

[خذ المزيد]

The OK™ mill - the most reliable and efficient mill for raw

June 27, 2017. The OK mill has been FLSmidth’s standard cement vertical roller mill (VRM) since 1993. In 2017, FLSmidth also introduced the OK raw mill for raw material grinding, designed with the same proven design as the OK cement mill. The common mill

[خذ المزيد]

sbm/sbm abb mill motor raw mill 425 fls.md at main

Contribute to jgw2023/sbm development by creating an account on GitHub.

[خذ المزيد]

Hydraulic Roller Press - FLSmidth

Upgrading a conventional ball mill with the Hydraulic Roller Press for semi-finish setups can increase production by up to 100 per cent or more, while also reducing specific power consumption by approximately 30 per cent. ... Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement ...

[خذ المزيد]

en/121/fls coal mill.md at main dinglei2022/en GitHub

Contribute to dinglei2022/en development by creating an account on GitHub.

[خذ المزيد]

sbmchina/sbm vertical roller mill fls.md at main

Find and fix vulnerabilities Codespaces. Instant dev environments

[خذ المزيد]

ATOX® Coal Mill - FLSmidth

A compact coal mill solution for grinding virtually any type of raw coal. Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate ...

[خذ المزيد]

Roller mill - ATOX® COAL - FLSmidth Dorr-Oliver Eimco

The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate piece of equipment for crushing. The coal mill can also grind petroleum coke and anthracite down to a fineness below 5% +90 micromillimeters (mm) when coupled with a variable ...

[خذ المزيد]

(PDF) DESIGN AND ANALYSIS OF BALL MILL

The present work is aimed at further understanding of the design studies of feed chute for powdery feed material and truck using FEM and DEM software and to use in the further designs of ball mills. 1.1 FLS UMS

[خذ المزيد]

Vendor India Flsmidth - Atox VRM Mill

A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force

[خذ المزيد]

MillCarb™ Vertical Roller Mill (VRM) Update

1 天前 Progress report on Welding Alloys’ hardfacing repair of vertical roller mill (VRM) rolls for a Malaysian power plant. Our last article about this Welding Alloys Far East Integra™service team VRM repair project

[خذ المزيد]

ATOX Raw Mill - [PDF Document]

2014年11月8日 The ATOX raw mill has demonstrated to be suitable for grinding virtually all types of raw materials. • Grindability varying from very easy to grind to very hard to grind, say from less than 3 kWh/t to more than 11 kWh/t for the mill drive. • Moisture in feed material varying from less than 1 % to more than 20 %.

[خذ المزيد]

FLS Ok Mill Common Platform WEB PDF PDF Mill

2019年4月18日 FLS Ok mill common platform WEB.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.

[خذ المزيد]

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

2019年4月21日 The dimensions/areas for a chute should as far as possible be chosen according to. the outlet flange for a machine. The smallest side length in a chute must be min. 5 times the max lump size. Min. chute size for lumpy material: 250mm x 250mm (0,063 m2). Min. chute size for powdery material: ø200 (0.04 m2).

[خذ المزيد]

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

MPS 3070 BK coal mill, Jaypee Cement Balaji, India. MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia. MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil. MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China.

[خذ المزيد]

QCX® Centaurus® Combined Mill and Press - FLSmidth

Download. The QCX Centaurus Combined Mill and Press is a compact unit that consists of an automatic fine grinding mill and an automatic pelletising press. It makes x-ray sample preparation easy and requires little assistance from your lab staff. It can operate as a stand-alone system or be integrated with linear or robotic automated laboratories.

[خذ المزيد]- المتتالية طحن تأثير في الكرة طاحونة

- تحليل ELECON كسارة غربال 50 مم سحق الفحم شاشات

- مصانع آلة التعدين

- معدات طحن عدسة شراء عبر الإنترنت

- صنع الفلبين كسارة الصخور

- متر مكعب إلى طن متري من 3 4 حجر الكلي

- مدیر سنگ شکن و کارخانه معدن

- قدرة كسارة مخروطية 500tph

- منتجات خام الحديد الاتصالات معدات التعدين

- المغذية الدوارة الرأسي مطحنة

- سنگ شکن فکی قیف specifikasi

- المطرقة محطم سم دردشة على الانترنت

- هي أنواع الالياف المستعملة في صنع لملا

- خريطة تعدين الفحم الاندونيسية

- كسارة الحجر المحمولة جاكارتا

- طريقة تركيب سير ماكينة شروكي

- سم المعدني من 60 طن كسارة الحجر

- مطحنة المطرقة لخام الذهب

- استخدام الأجهزة الرمال الميكانيكية في تاميل نادو

- استخدام مسحوق مطحنة الصناعية

- فرآیند سنگ آهنی با آسیاب توپ

- كيفية تقييم خام في المحجر

- المعادن الحزام الناقل هارجا جاكرتا

- تحليل gcv للفحم adb

- معدات إنشاء الطرق

- عملية التعدين المعادن

- زغال سنگ له همراه

- معدات مناجم الفحم تحت الأرض

- أسمنت الكرة مطحنة الشركة المصنعة في الهند

- کمربند نقاله در اندونزی

© Copyright - PETER&X محطم