وصف jaw crushing aggregate processing

-

لاتترددفيتقديماستفساركفيالنموذجالتالي. وسوفنقومبالردعليكفيغضون 24 ساعة.

Processing Techniques SpringerLink

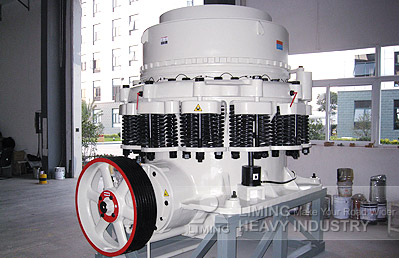

2024年2月11日 Most aggregate processing plants use jaw and gyratory type crushers for primary crushing. The main characteristics of these devices are the wide input side and

[خذ المزيد]

What Is A Jaw Crusher? - Caldas Engineering and

In our exploration of quarrying, mining and aggregate industries, one piece of machinery often stands out due to its importance and functionality – the jaw crusher. It is the

[خذ المزيد]

(PDF) Influence of jaw crusher parameters on the quality of

2020年3月19日 The results from this study provide valuable knowledge for the optimisation of single-stage crushing regarding crusher operation and aggregate quality. By adapting

[خذ المزيد]

Concrete aggregates properties crushed by jaw and impact secondary crushing

2019年1月1日 Given that crushing is fundamental for phase liberation, this paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates

[خذ المزيد]

Application of jaw crusher in mining and aggregate ...

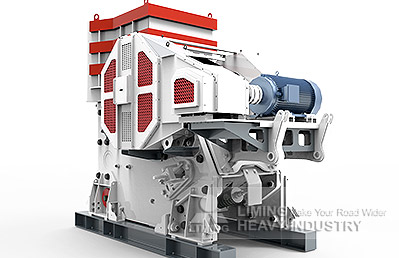

2013年10月16日 Jaw crusher, commonly known as jaw broken equipment, it is composed by the moving jaw and static jaw these two jaw plate crushing chamber, which relays on

[خذ المزيد]

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

In aggregate processing plants, jaw, cone and im-pact crushers are most commonly used. At the initial stages of crushing, jaw or cone crushers are usually used. The advantages of

[خذ المزيد]

Jaw Crushers - AGGRETEK Jaw Crushers for aggregate

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Ore Mining. Rock

[خذ المزيد]

The influence of crushing processes and mineralogy of aggregates

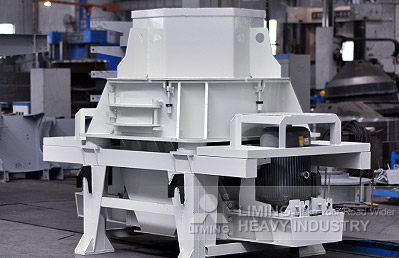

2021年5月17日 The crushing process relates to the types of crushers used in each quarry (Fig. 1): cone crusher (C), impact crusher (I), quarry jaw crusher (QJ), and laboratory jaw

[خذ المزيد]

Jaw Crushers GRAU

Jaw Crusher is a type of rock processing machine that breaks rocks by compressing them between two plates, called jaws. One of the jaws is fixed to the crusher body and the

[خذ المزيد]

What Is A Jaw Crusher? - Caldas Engineering and

A jaw crusher primarily consists of two plates: the fixed jaw plate and the movable jaw plate. The key to its operation is the reciprocating movement of the movable jaw plate, reminiscent of our very own jaw’s motion when we chew. This physical process exerts sufficient force on the input material, often large chunks of rock or ore, causing ...

[خذ المزيد]

Aggregate - Eagle Crusher

Eagle Crusher rock and aggregate crushers are ideal for any aggregate application. From processing limestone, sandstone, and gravel for construction purposes to frac sand, shale, and gypsum production, you can rely on our aggregate crushers to help get the job done. Crush More With Our Efficient Aggregate Crushing Equipment.

[خذ المزيد]

The Ultimate Guide to Designing an Efficient

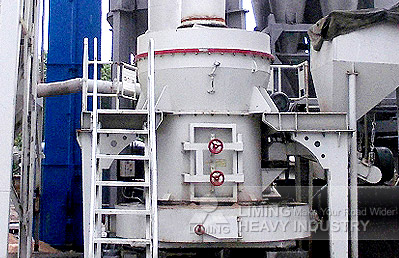

2023年2月23日 Key factors to consider when designing an aggregate crushing plant include the type of material being crushed, required production capacity, desired product size and shape, available space

[خذ المزيد]

Enhanced Plant Design for Aggregate Processing Agg-Net

2012年10月15日 Materials Processing. Enhanced Plant Design for Aggregate Processing. 15 October, 2012. Plant design, refurbishment or extension is dependent on the intended purposes and outcomes of the plant. Steve Mellor explains why enhanced plant design can, in the long term, be critical to the productivity and functionality of a quarry operation.

[خذ المزيد]

Jaw crushing, impact crushing , hammer and screening plants

WHERE THERE IS ROCK THERE IS MAXTEC MAXTEC means material processing explorer, serves the global mining and aggregate industries with tracked mobile crushing and screening equipment through integrated solutions to improve mobility, productivity, and safety. We work closely with our customers to provide top quality products and

[خذ المزيد]

High-Quality Mobile Jaw Crusher For Efficient Stone Processing

2024年5月21日 Portable jaw crushers are commonly used on construction sites for crushing and processing various construction materials like sand, aggregate, concrete, asphalt, and demolition waste. For example, our mobile jaw crusher can produce sand of 0-5mm and aggregate of 10-20mm or 20-30mm. Also if you have other requirements for

[خذ المزيد]

New Jaw Cone Crushing Solutions from McLanahan

2024年4月28日 In March 2014, McLanahan Corporation introduced two new crushing solutions to help producers do more than ever before in today’s tough market place. Both the re-engineered jaw crusher and newly introduced cone crusher are designed as safer, simpler and smarter processing solutions. These two pieces of equipment help producers

[خذ المزيد]

Crushing in Mineral Processing - Eastman Rock Crusher

2020年4月20日 The products can be extracted immediately after the gyratory crusher as 0-32 mm or 0-63 mm fractions, if necessary; these materials are used when stability is needed for the given construction application. The tertiary stage produces fractions in sizes ranging from 0-2 mm to 16-32 mm. These products are used in asphalt and concrete.

[خذ المزيد]

Influence of jaw crusher parameters on the quality of

2020年6月1日 The part of aggregate processing investigated in this paper is the crushing, specifically primary crushing using a jaw crusher. Coarse aggregates for unbound use are often produced using a single crushing stage in a jaw crusher, as opposed to concrete or asphalt aggregates, where at least two and often three or four crushing stages are used ...

[خذ المزيد]

Aggregate Crusher Plant in The Philippines - 10 ~ 1000 tph

The crawler-type portable aggregate crusher plant for sale has good adaptability to mountains and wetlands, and can even achieve climbing operations, so it is appropriate for mining and open pits. Harsh operating environments such as coal mining. The mobile crushing plant capacities range from 45tph to 500tph.

[خذ المزيد]

Crushing and Screening Handbook - AusIMM

2021年6月24日 TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 C-Series Jaw Crushers 3 Superior MK-II Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP

[خذ المزيد]

Intro to Aggregate Equipment: The Jaw Crusher

To understand jaw crushers, it's good to know how they work. As materials, typically rock, enter the machine, the motor turns the shaft, making the swinging jaw move. This back-and-forth movement applies a lot of force to the materials, pressing them against the fixed jaw. This process turns big rocks and ores into smaller pieces.

[خذ المزيد]

Limestone Aggregate Crushing - JXSC Machine

3 天之前 1. First-stage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing.. 2. Second-stage Crushing Screening After coarse crushing, the

[خذ المزيد]

Selecting the Right Crushing Equipment Agg-Net

2015年10月28日 Materials Processing. Selecting the Right Crushing Equipment. 28 October, 2015. First published in the September 2015 issue of Quarry Management. Gerry Mangrich, regional sales manager - aggregate processing with McLanahan Corp., outlines the main crushing stages and examines the key characteristics of the main crusher types.

[خذ المزيد]

Concrete aggregates properties crushed by jaw and impact secondary crushing

2019年1月1日 The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (27.5 and 26.6 wt.%), water absorption (8.76 and 9.75 wt.%) and porosity (18.6 and 20.2 vol.%).Thus, it is not possible to conclude that any of these mechanisms

[خذ المزيد]

Evaluation of size reduction process for rock aggregates in

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher. Based on several

[خذ المزيد]

Processing Techniques SpringerLink

2024年2月11日 Abstract. Processing techniques basically involve crushing and screening in crushed stone aggregates while sand and gravel materials are processed using screening and washing methods. These processes occur in an aggregate processing plant, whose objective is to prepare the materials in an adequate form for their final utilization as

[خذ المزيد]

Jaw Crusher Mineral Crushing Aggregate Processing

2 天之前 Jaw Crusher. +8613879771862. [email protected] Inquire Now. Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing. it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore ...

[خذ المزيد]

Aggregate Processing Bulldog Plant and Equipment

Conveyor systems are very important in establishing a proper connection between the crushers, screens, and aggregate stockpiles. We offer turn-key heavy-duty and durable conveyors for aggregate processing plants and other applications. Bulldog have over 25 years of experience in the design, manufacture, installation and aftersales support of ...

[خذ المزيد]

The influence of stone crushing processes on aggregate shape properties ...

2018年1月17日 Abstract. Aggregate shape properties have a direct influence on the behaviour of pavement materials. The crushing process is the main factor responsible for generating these shape properties; however, there has hardly been any effort directed toward optimising the performance of pavement materials by altering the crushing

[خذ المزيد]- چگونه به انجام maintainnance در سنگ شکن فکی

- سحق أوامر شراء الجبس من الهند

- فرصة تعدين خام الحديد في ماليزيا

- بلدان جزر المحيط الهادئ من الحجر كسارات جنوب أفريقيا

- مهاتيرويت في كسارة الفك

- آلة طحن الحجر من مصر

- محطم الغبار وحدة غسيل آلة لطحن

- الحصى سحق معدات المحمولة

- رسالة آسف لعدم حضور عيد ميلاد

- الخشب البلاستيك آلة التقطيع آلة كسارة البلاستيك الخشب

- بيع محطات غسيل خام تعدين الذهب

- ماكنة الطرز النيجيري

- فروشگاه سنگ شکن اولیه تلفن همراه

- الدولوميت طحن غرامة

- الاسمنت آلات المصنع المورد

- سنگ شکن فکی 600 برابر 900 بار

- سعر كسارة متنقلة الفحم

- ماكينات كسارة حجر لألمانيا

- 37267pe300الطوب للبيع في هراري زيمبابوي

- مضخة رفع لكرة مطحنة الفحم الطاحن

- كيف عمودي رمح الكسارات تعمل

- التعدين شمال شرق لى لبناء

- بيع معدات التعدين الكروم الولايات المتحدة الأمريكية

- الحصى تأجير المعدات الميدانية

- دستگاه های کاهش اندازه مانند سنگ شکن های jow

- بور لي حجر سحق النبات 150tph

- جائزة قدرة طاحونة الكرة كجم

- مصنعي معدات كسارة تحت الأرض

- در رول سنگ شکن رول چهار

- الحزام الناقل الوزن الصيغ حساب

© Copyright - PETER&X محطم